Hydraulic Cylinder Manufacturer

Hydraulic Cylinder

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Hydraulic Cylinders

Hydraulic cylinders are often the unsung heroes of most heavy-duty applications. From construction machinery to industrial equipment, these components play an indispensable role in providing linear motion and high force based on hydraulic fluid dynamics.

Based on Pascal’s Law, hydraulic cylinders are able to transmit force throughout the hydraulic fluid stored within, converting this force into motion. When hydraulic fluid is pumped into the cylinder barrel, the fluid pushes the piston, which then pushes the rod, creating motion.

Understanding hydraulic cylinders is essential for anyone involved in mechanical design or operation. With a myriad of uses, these components are not just parts but the backbone of modern machinery.

Why Choose Hydraulic Cylinders?

- High Force: Can generate a significant amount of force relative to their size.

- Precision: Offer excellent control and accuracy.

- Versatility: Used in a variety of applications and environments.

What Are Hydraulic Cylinders Used For?

Hydraulic cylinders are ubiquitous in modern machinery and play a crucial role in a wide range of mechanical applications. By converting hydraulic fluid pressure into mechanical energy, these cylinders provide the muscle for systems requiring linear motion.

- Material Handling

- Assembly Lines

- Excavators

- Forklifts

- Cranes

- Agricultural Machinery

- Construction Equipments

- Forest Industry

- Marine & Offshore

- Earth Moving Equipments

- Civil Infrastructure

- Emergency Vehicles

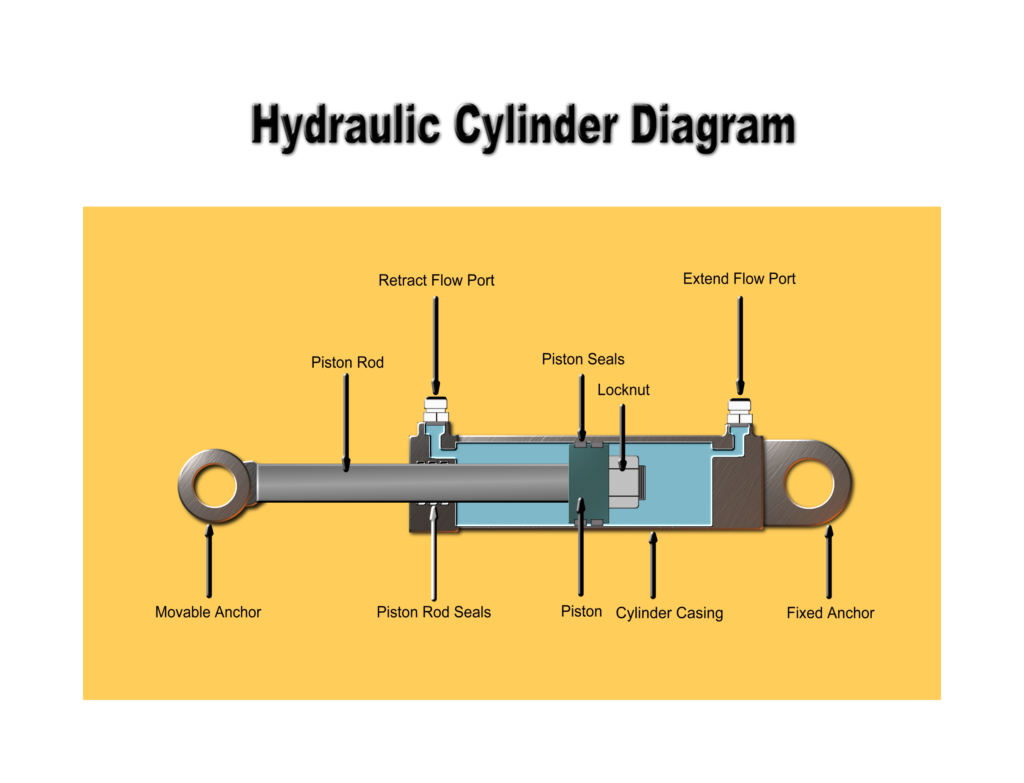

Hydraulic Cylinder Parts

Understanding the parts of a hydraulic cylinder is essential for anyone involved in the purchasing, maintenance, or operation of hydraulic systems. Each component is engineered to perform a specific role, and the cylinder’s effectiveness relies on the quality and compatibility of its parts.

Cylinder Barrel

Often made from high-strength steel or stainless steel to withstand internal pressures and acts as the pressure chamber that houses the hydraulic fluid and piston.

Piston

The material used for hydraulic cylinder pistons can vary depending on the application, the pressures involved, and the environment in which the cylinder will operate. However, some common materials used for hydraulic cylinder pistons include carbon steel, stainless steel, aluminum, bronze or brass, cast iron and composite materials.

It may have grooves to accommodate seals for preventing fluid leakage.

Piston Rod

Typically made from chrome-plated steel for durability and corrosion resistance and provides the mechanical output from the cylinder.

End Cap(Spherical Tang)

Usually made of the same material as the barrel for structural consistency.

It seals the bottom end of the cylinder barrel, often contains the fluid port.

Cylinder Head

Houses seals and sometimes wiper seals to prevent internal leakage and contamination.

Sealing Components

O Rings: Usually made of nitrile rubber or other elastomeric materials and creates a tight seal between the cylinder’s various components.

Wiper Seals: Removes contaminants from the piston rod as it retracts into the cylinder.

Rod Seals: Located inside the rod gland, often in combination with wiper seals. Ensures that hydraulic fluid doesn’t escape the system, maintaining pressure.

How Does Hydraulic Cylinder Work?

How exactly does a hydraulic cylinder work? This guide breaks down the operational principles behind this essential device.

- Fluid Intake: Hydraulic fluid is pumped into the cylinder barrel through an inlet port located on the end cap. Then the fluid enters the chamber behind the piston.

- Piston Activation: The hydraulic fluid pressure acts on the surface area of the piston. This creates a force that pushes the piston forward.

- Linear Motion: As the piston moves, it drives the piston rod, which extends out of the cylinder.

- Retraction: To retract the piston rod, hydraulic fluid is either released from the chamber or introduced into another chamber on the opposite side of the piston.

- Fluid Exit: Once the desired movement is achieved, the hydraulic fluid is released or redirected back into the reservoir for future cycles.

Considerations When Buying Hydraulic Cylinders

When buying hydraulic cylinders, there are several important factors to consider in order to make an informed decision. These considerations will help ensure that you purchase a product that not only meets your specifications but also offers reliable performance, longevity, and good value for money. Here are some of the key considerations:

Technical Specifications

Bore Diameter: The internal diameter of the cylinder barrel is crucial for determining the force the cylinder can exert.

Stroke Length: This is the distance the piston can travel in the cylinder, which affects how much work can be done.

Rod Diameter: The diameter of the rod impacts the cylinder’s overall strength and speed.

Working Pressure: The pressure at which the cylinder can safely operate.

Seal Types: Different seals have different temperature and pressure tolerances.

Material: The type of material used for the barrel and piston rod, usually steel or aluminum, depending on the application.

Supplier Considerations

Reputation: Research the supplier’s reputation in the market.

Response Time: A supplier’s response time can be critical, especially for after-sales service.

Logistics: Check the shipping time and whether the supplier can meet your schedule.

Quality & Certification

Quality Standards: Look for certifications like ISO to ensure quality manufacturing.

Quality Inspection: Ensure that a rigorous quality inspection process is in place.

Warranty: A good warranty period is often a sign of quality.

After-Sales Service

Technical Support: Availability of technical support post-purchase.

Parts Availability: Ensure that parts for the hydraulic cylinder are readily available.

Return Policy: Understand the return policy in case the product doesn’t meet your needs.

Hydraulic Cylinders Types By Working Mechanism

Single Acting Cylinder

Single acting hydraulic cylinders have a simple, single working port design that allows power in one direction and then uses gravity or mechanical force to return to its non-pressurized position. Single acting hydraulic cylinders are low maintenance and compatible with basically any type of machinery. This type of hydraulic cylinder works well for factory automation, such as food processing and industrial manufacturing.

Double Acting Cylinder

Double acting hydraulic cylinders are powered in both directions, enabling the cylinder to deliver unidirectional power. This type of hydraulic cylinder is ideal for heavy-duty industrial, mobile, manufacturing, and construction equipment because it uses power instead of gravity to bring the cylinder back down. Use double acting hydraulic cylinders in any application requiring force while the cylinder is extending and retracting.

Hydraulic Cylinders Types By Design

Telescopic Cylinder

This cylinder type consists of several stages or sleeves, which can extend much further than a single-stage cylinder of the same collapsed length.

Telescopic hydraulic cylinders utilize multiple nested stages, achieving a long working stroke in compact/retracted form. HUANUO Hydraulics designs and engineers application-specific telescopic cylinders, purpose-built to withstand demanding applications and work environments. An experienced engineering team helps you work through design considerations to ensure your cylinder meets your requirements.

Single Stage Cylinder

A single-stage hydraulic cylinder is a type of hydraulic cylinder that consists of a single chamber in which hydraulic fluid acts to produce motion in one direction. It is the simplest form of a hydraulic cylinder.

They are commonly used in applications where simple linear movement is required, such as lifting or pushing loads in a single direction. They are relatively straightforward in design and operation, making them cost-effective and easy to maintain.

Hydraulic Cylinders Types By Structure

Tie Rod Cylinder

A tie rod hydraulic cylinder, also known as a “round body cylinder,” is a type of hydraulic cylinder that is characterized by its construction using tie rods. These tie rods are threaded rods that run the length of the cylinder and are used to hold together the various components of the cylinder.

Welded Cylinder

A welded hydraulic cylinder, also known as a “welded body cylinder” or “welded construction cylinder,” is a type of hydraulic cylinder with a barrel that is fabricated from a single piece of steel through welding. This means that the cylinder barrel is created by welding together the necessary components, resulting in a seamless and integrated structure.

Welded cylinders are commonly used in applications where space is limited or where a compact, strong, and reliable cylinder is needed. They are often found in heavy machinery, construction equipment, and other industrial applications.

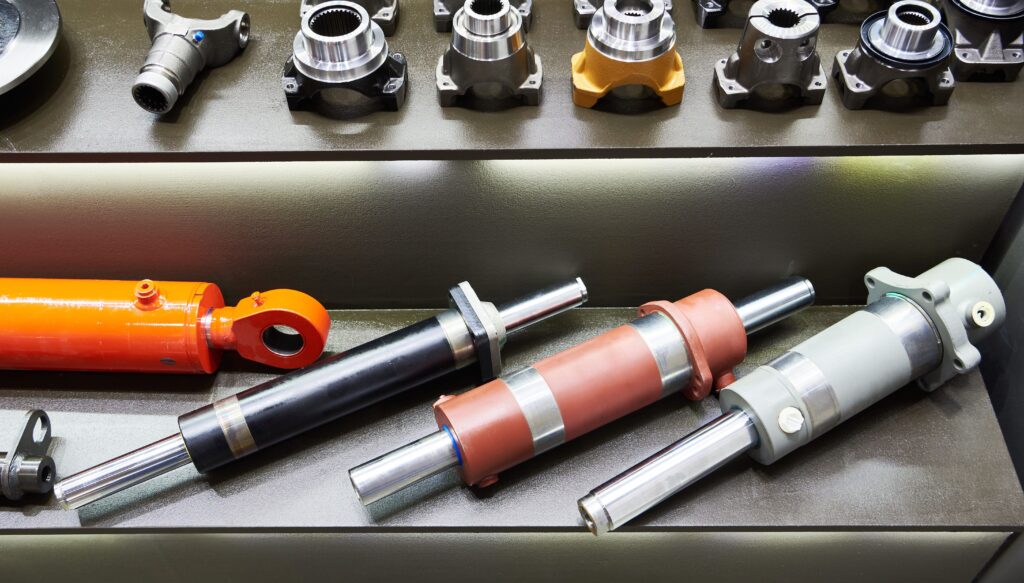

Purpose-Build Hydraulic Cylinders&Components Catalog

Every Detail Counts

Meticulously developed to elevate your hydraulic cylinder experience, HUANUO Hydraulics’ purpose-built catalog delivers the comprehensive information you want. Whether your needs are for components, custom, pre-engineered, or unique hydraulic cylinder solutions, our catalog has you covered. Experience why HUANUO Hydraulics is Engineered to Move Your Business.

When you register for our print catalog, you will also be sent a link to the downloadable PDF version for easy and instant catalog access at your desk or in the field. Within twenty-four hours, registered OEMs and resellers can unlock complete stocking information and current component pricing via our website. These enhanced specifications help you make accurate and fully-informed decisions. At HUANUO Hydraulics, quality is a critical part of everything we do. Discover our high-quality catalog options and explore your purpose-built hydraulic cylinder choices today.

New features include:

- Thorough breakdowns for product lines

- Expanded parts offerings

- Online tools for streamlined quoting

- Common hydraulic cylinder formulas

Print Catalog

Register below to be sent a hard copy of our current catalog. You will also be sent a link to download the PDF version to view on your computer or mobile devices.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right component you want.

Mobile: +86-18006712375

Mail: eric@huanuohyd.com