Latest News

The latest and greatest project news

What is a Hydraulic Cylinder?

Do you know what is a hydraulic cylinder or hydraulic actuator? Or whether you have some doubts about this unfamiliar words or definition? Or want to learn more about it, such as hydraulic cylinder components, hydraulic cylinder working principle, hydraulic cylinder types etc? Or concern more about hydraulic cylinder repairing, hydraulic cylinder customization? Understanding these basic info is essential for you to know and how to choose a suitable cylinder.

As a professional manufacturer and end user of hydraulic cylinders, today I will show you a deep dive into hydraulic cylinders and discuss the following topics with you from the perspective of someone who has experienced them, including the most commonly asked questions.

What is a Hydraulic Actuator?

A hydraulic cylinder or hydraulic actuator is a mechanical actuator that is used to provide unidirectional force through unidirectional stroke. According to our experience, it has many applications, primarily in the construction equipment, manufacturing machinery, and engineering industry. The basic idea of a hydraulic cylinder is simple: it contains a hollow cylinder barrel with a piston inside it, and then the movement of the piston is controlled by the flow of hydraulic fluid. Hydraulic actuators are part of a hydraulic system, which usually includes a hydraulic pump, reservoir, valves, electric motor and piping to convey the fluid.

They are applied in vast industries, such as aerial working platform, agriculture machinery, hydraulic presses, construction equipment, scissor table lift, Two-post car lift etc. In other words, they are mainly used for pressing, lifting, pulling something which need extra force.

When you are operating a forklift, a crane or a sanitation vehicle, you have used the cylinder already.

How does a Hydraulic cylinder work?

The working principle of a hydraulic actuator is based on Pascal’s law, which states that pressure applied to a confined fluid is transmitted undiminished in all directions. Below is a step-by-step explanation of how a hydraulic actuator works:

Basic Steps:

- Fluid Supply: A hydraulic pump draws fluid from a reservoir and then pressurizes it. The hydraulic fluid is then directed towards the actuator through a series of valves and pipes.

- Control Valves: Control valves regulate the flow and direction of the hydraulic fluid, determining when, where, and how the actuator will move.

Fluid Transfer: The pressurized hydraulic fluid is transferred through the hydraulic system to the actuator, entering it via ports.

Actuator Activation: Once the hydraulic fluid reaches the actuator (commonly a hydraulic cylinder or a rotary actuator), it pushes against a piston or a set of gears.

Linear Actuators: In the case of a hydraulic cylinder, the fluid pushes against a piston, generating linear motion.

Rotary Actuators: In rotary actuators, the fluid exerts pressure on a set of gears or a rotor, generating rotational motion.

Mechanical Work: The movement of the piston or gears converts the hydraulic energy into mechanical energy, which can be used to perform work like lifting a load, pulling, pushing, or rotating an object.

Retraction: For double-acting actuators, the hydraulic fluid can be pumped into the other side of the piston to retract it. Single-acting actuators usually use a spring or some external force for retraction.

Exhaust: After the actuator has completed its motion, the hydraulic fluid is usually returned to the reservoir, either to be recycled or expelled, depending on the system.

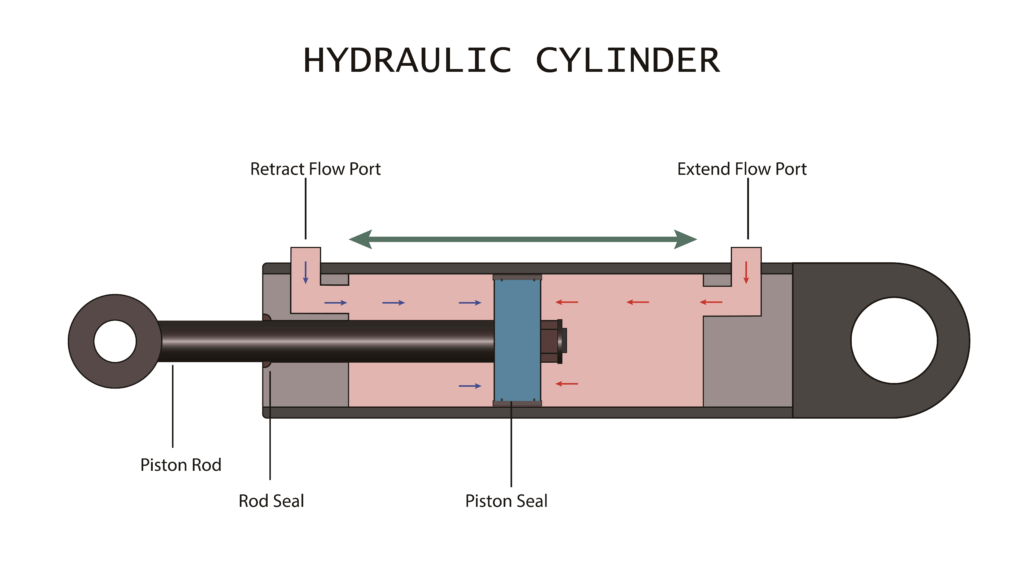

Hydraulic cylinder components

Hydraulic cylinder consist of a lot of components. Understanding each component is essential for anyone involved in the purchasing, maintenance, repairing or operation of hydraulic systems. Each component is designed to perform a specific role, and the cylinder’s effectiveness relies on the quality and compatibility of its parts. Here’s a breakdown of these components:

- Cylinder Barrel: The cylinder barrel is the main body of the hydraulic cylinder and is responsible for holding the pressure of the hydraulic fluid. Often made from high-strength steel or stainless steel to withstand internal pressures and acts as the pressure chamber that houses the hydraulic fluid and piston.

- Piston: The material used for hydraulic cylinder pistons can vary depending on the application, the pressures involved, and the environment in which the cylinder will operate. However, some common materials used for hydraulic cylinder pistons include carbon steel, stainless steel, aluminum, bronze or brass, cast iron and composite materials. It may have grooves to accommodate seals for preventing fluid leakage.

- Piston Rod: Typically made from chrome-plated steel for durability and corrosion resistance and provides the mechanical output from the cylinder. Attached to the piston, the piston rod extends out from the cylinder and transfers the mechanical force generated inside the cylinder to the external load.

- End Caps: Usually made of the same material as the barrel for structural consistency. It seals the bottom end of the cylinder barrel, often contains the fluid port. There are two end caps in a hydraulic cylinder:

- Head Cap: The end through which the piston rod exits the cylinder.

- Base Cap: The opposite end that usually encloses the cylinder.

- Seals: Seals are essential for preventing the leakage of hydraulic fluid.

- Rod Seals: Located inside the rod gland, often in combination with wiper seals. Ensures that hydraulic fluid doesn’t escape the system, maintaining pressure.

- O Rings: Usually made of nitrile rubber or other elastomeric materials and creates a tight seal between the cylinder’s various components.

- Wiper Seals: Removes contaminants from the piston rod as it retracts into the cylinder.

Different types of Hydraulic cylinders

Hydraulic cylinders are essential components in various industrial machinery, mobile machinery, and equipment. These cylinders provide the force required for many types of operations, from lifting and lowering to pushing and pulling. Here are some common types of hydraulic cylinders:

Single-Acting Cylinders

A Single-Acting Cylinder is a type of hydraulic cylinder that operates with hydraulic fluid acting on one side of the piston to create movement in one direction (usually extending the piston). The retraction of the piston is typically accomplished by either an external force, like gravity or a spring, rather than hydraulic pressure.

Double-Acting Cylinders

A Double-Acting Cylinder is a type of hydraulic cylinder in which hydraulic fluid is used to move the piston in both directions—both extending and retracting. In Double-acting cylinders, they use hydraulic pressure for both actions.

Telescopic Cylinders

These are a special type of double-acting cylinder that extends much longer than a standard cylinder. They are often used in machinery that requires long stroke lengths but has limited installation space, making them a good fit for advanced control systems.

Tandem Cylinders

In tandem cylinders, usually two or more cylinders connected in a series or parallel arrangement to achieve greater force or stroke length.

Tie Rod Cylinders

A tie rod hydraulic cylinder, also known as a “round body cylinder,” is a type of hydraulic cylinder that is characterized by its construction using tie rods. These tie rods are threaded rods that run the length of the cylinder and are used to hold together the various components of the cylinder.

Welded Cylinders

Welded hydraulic cylinder is a type of hydraulic cylinder with a barrel that is fabricated from a single piece of steel through welding. This means that the cylinder barrel is created by welding together the necessary components, resulting in a seamless and integrated structure.

They are commonly used in applications where space is limited or where a compact, strong, and reliable cylinder is needed. They are often found in heavy machinery, construction equipment, and other industrial applications.

hydraulic VS pneumatic cylinders

Both hydraulic and pneumatic cylinders are used to convert fluid power into mechanical motion, but they operate under different principles and are suitable for different applications. Here’s a comparison and difference between the two:

Operating Principle

Hydraulic Cylinder: Operates using an incompressible fluid, usually hydraulic oil.

Pneumatic Cylinder: Operates using compressed air or another compressible gas.

Components: Both have similar components like a cylinder barrel, piston, and piston rod, but hydraulic cylinders usually have more robust seals to handle higher pressures.

Force and Speed

Hydraulic Cylinder: Capable of producing much higher force compared to pneumatic cylinders due to higher fluid pressure.

Pneumatic Cylinder: Generally faster in terms of piston speed, but produce less force.

Control Precision

Hydraulic Cylinder: Offers better control over position, velocity, and force.

Pneumatic Cylinder: Generally less precise in control compared to hydraulic cylinders.

Application Areas

Hydraulic Cylinder: Construction machinery, industrial applications, heavy lifting.

Pneumatic Cylinder: Automation, robotics, light-duty applications where speed is more critical than force.

Hydraulic Cylinder Advantages

Hydraulic cylinders offer a range of advantages that make them well-suited for various industrial and mobile applications, here we have listed some key points according to our own experience and feedback from our clients.

- High Force Generation: Hydraulic cylinders can produce a significantly higher amount of force compared to pneumatic and mechanical systems due to the incompressible nature of hydraulic fluid, making them ideal for heavy-duty industrial applications.

- Control & Precision: Hydraulics offer superior control and precision, especially when it comes to stopping, starting, and changing directions. This can be crucial in operations where exact movements are needed.

- Minimal Energy Loss: Hydraulic systems are generally more effective in terms of energy transfer, as there’s minimal loss of energy between the hydraulic pump and the cylinder. This results in a more efficient operation.

- Durability: These cylinders are robust and can endure more wear and tear, often providing a longer lifespan compared to their pneumatic counterparts.

- Noise Reduction: Hydraulic systems can be quieter than pneumatic systems, which is an advantage in settings where noise reduction is important.

- Stable Holding Capability: If your application requires holding a load steady for a prolonged period, hydraulic cylinders are often more suited to this task than pneumatic cylinders.

Hydraulic Cylinder Disadvantages

While hydraulic cylinders offer many advantages, there are also some aspects where they may not be as favorable when compared to pneumatic cylinders.

- Initial Costs: Hydraulic systems generally come with a higher initial investment compared to pneumatic systems. This is something to consider if you’re budget-sensitive.

- Complexity of Setup: Hydraulics offer superior control and precision, especially when it comes to stopping, starting, and changing directions. This can be crucial in operations where exact movements are needed.Hydraulic cylinders often require a more complex setup, including a hydraulic fluid reservoir, pumps, and valves. This may lengthen the installation process.

- Fluid Leakage: One of the more obvious downsides is the risk of hydraulic fluid leaks. These not only can be messy but also present an environmental concern.

- Size and Weight: Due to the components involved, a hydraulic system may end up being bulkier and heavier than a pneumatic one, which could be a limitation in some settings.

Pneumatic Cylinder Advantages

Comparing with hydraulic cylinder, first, pneumatic systems are generally easier and quicker to install. With fewer components than hydraulic systems, setting them up is typically more straightforward. Second, unlike hydraulic systems, pneumatic systems are less affected by temperature variations, making them more versatile in different operating environments. Third, Pneumatic cylinders can operate at very high speeds, which can be an advantage in applications where rapid motion is required. Last, pneumatic cylinders are often lighter than their hydraulic counterparts, which could be an advantage in mobile applications or where weight is a crucial factor.

Pneumatic Cylinder Disadvantages

- Pneumatic cylinders generally offer less force output compared to hydraulic cylinders, which may not be ideal for heavy-duty tasks.

- Pneumatic cylinders may not be as effective as hydraulic cylinders in applications that require a load to be held in position for extended periods.

- Pneumatic systems require clean, dry air to function optimally. Moisture or contaminants in the air can lead to reduced performance and more frequent maintenance.

- While fast and efficient, pneumatic cylinders might not offer the same level of precision and control that you can get with hydraulic systems.

How to choose a hydraulic cylinder?

Choosing a hydraulic actuator involves several factors that must be considered to ensure that it meets the specifications and requirements of your application. Let’s get into the technical details of selecting a hydraulic actuator, focusing on key specifications like bore size, rod size, and stroke length etc.

- Determine Application Requirements: The first step is to understand what your hydraulic system needs to accomplish. This includes knowing the force required, the speed of the operation, and the distance the actuator needs to move.

- Calculate Required Force:

The force required can be calculated using the formula: F=Load+Friction+Gravity This gives you the force that the hydraulic actuator needs to exert.

Selecting Bore Size: The bore size of a hydraulic cylinder is critical for determining its force capabilities. The force F exerted by a hydraulic cylinder is given by: F=P×A.

Where: F is the force, P is the operating hydraulic pressure, A is the piston area, which is directly related to the bore diameter.

- Selecting Rod Size: The rod size affects the strength and stability of the actuator. A rod that is too small may buckle under load, while a rod that is too large may be overkill and add unnecessary cost.

For push applications, the rod size is less critical. For pull applications, a stronger rod may be required.

- Determine Stroke Length: The stroke length is the distance the actuator will move. This needs to be matched precisely to your application requirements. Ensure there is a bit of extra length to account for any mechanical “over-travel.”

- Speed Requirements: The speed at which the actuator moves is generally determined by the flow rate of the hydraulic fluid, which can be calculated using: Speed=Flow Rate/Piston Area

- Other Factors to Consider: Mounting Options, Seals and Cushions, Material.

What are hydraulic cylinders used for?

Hydraulic cylinders are used in a wide range of industrial and mobile applications to create linear motion and force in a straight line. They are a key component in hydraulic systems and are essentially a mechanical actuator, covering excavators, cranes, loaders, dump trucks, backhoes, tractors, mining machinery, aerial working platforms etc.

Hydraulic cylinder suppliers

As leading manufacturer and supplier of hydraulic components for 15 years, especially for hydraulic cylinders, we provide a wide range and top-notch quality customs cylinders to our clients. Below are some main types cylinders we supply:

- Single acting cylinders

- Double acting cylinders

- Welded cylinders

- Tie-rod cylinders

- Telescopic cylinders

- Agriculture cylinders

- Stainless steel cylinders

- Oil/Gas Drilling Cylinder

- Offshore cylinders

Recent Posts

Share This Story, Choose Your Platform.

Leave A Comment

Your email address will not be published. Required fields are marked *