Orbital Motor Manufacturer

Orbital Motor

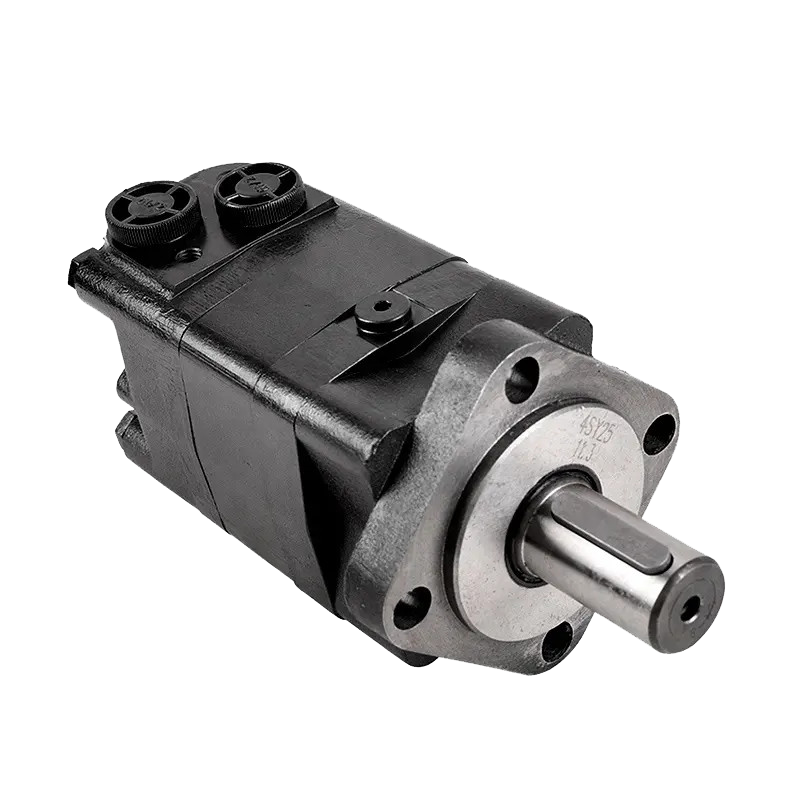

BMRS Series

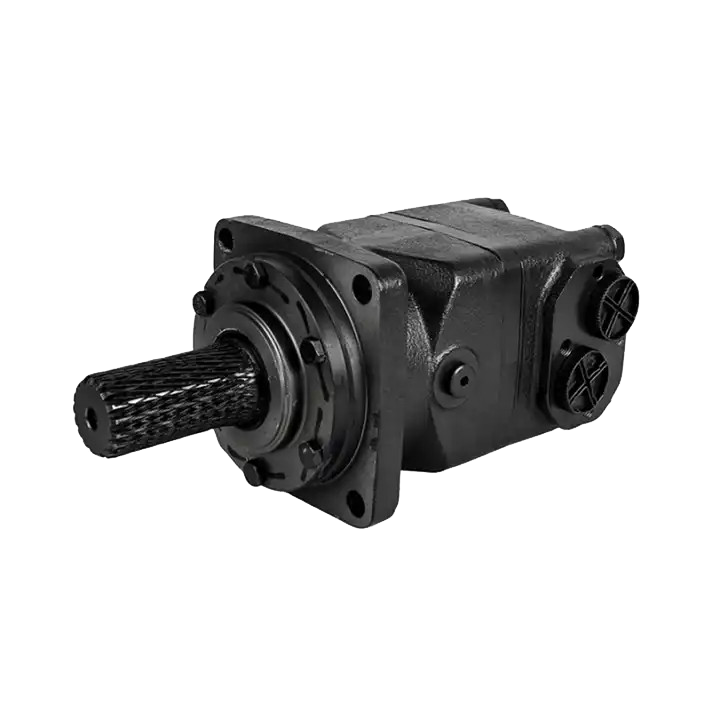

BMK6 Series

Char-Lynn 4000 Series

BMSY Series

BMT Series

OMT Series

BMK6 Series

BMT Series

BMM Series

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Orbital Motors

Hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into rotational motion. In essence, it is the rotary counterpart of a hydraulic cylinder, which produces linear motion.

Orbital motors, a subset of hydraulic motors, are known for their high torque at low speeds. They are used in a wide variety of applications, from agriculture and forestry to industrial machinery and construction equipment.

They are a versatile and essential component in many hydraulic systems. Knowing their types, how they work, and what to consider when purchasing can aid in making informed decisions.

Why Choose Orbital Motors?

Cost-Effectiveness

Generally, orbital motors are more cost-effective than other types of hydraulic motors when it comes to manufacturing and maintenance. This makes them a more affordable option without compromising on performance.

High Torque at Low Speeds

Orbital motors are known for delivering high torque even at low rotational speeds. This makes them ideal for applications requiring significant force without the need for high-speed rotation.

Versatility

Orbital motors are highly versatile and can be used in a wide range of applications, from mobile machinery to industrial applications and agricultural equipment.

High Efficiency

Orbital motors are designed to minimize internal friction, leading to high mechanical and volumetric efficiency. This is especially true for Geroller types, which use rollers instead of gears to reduce friction further.

Easy to Control

The control systems for orbital motors are typically simpler than those for other types of hydraulic motors, making them easier and more straightforward to operate.

Compact Design

These motors have a smaller footprint compared to other types of hydraulic motors, making them easy to integrate into systems where space is limited.

What Are Orbital Motors Used For?

Orbital motors are versatile and find application in a wide range of industries. Here’s a breakdown of some key sectors and specific uses:

- Agricultural Machinery: Tractors, Harvesters, Sprayers

- Construction Equipment: Excavators, Skid Steer Loaders, Concrete Mixers

- Industrial Machinery: Conveyors, Material Handling Equipment, Manufacturing Lines

- Mobile Equipment: Utility Trucks, Road Maintenance Vehicles

- Foresty: Log Splitters, Felling Equipment

- Marine Applications: Winches, Thrusters

- Renewable Energy: Wind Turbine Pitch Control

- Aerial Work Platforms: Scissor Lifts, Boom Lifts

- Mining: Drilling Rigs, Loaders

- Emergency Vehicles

Orbital Motor Manufacturing Parts

Orbital motors are complex pieces of machinery that consist of various components, each contributing to the motor’s overall functionality and performance. Below is a breakdown of the main parts commonly found in orbital motors:

Housing

The outer shell that protects the internal components.

Rotor Components

A set of inner and outer rotors (or rollers in the case of Geroller motors) that interact to create the pumping action.

Drive Shaft

Connects the motor to the load, transferring the rotational motion.

Needle Bearings

Support the drive shaft and resist axial forces.

Speed Sensors

Optional, used for feedback in controlled systems.

Shaft Seal

Prevents hydraulic fluid from leaking out of the motor around the drive shaft.

Disc Valve

Used in some designs for better control of fluid flow, particularly in high-pressure applications.

Retaining Rings

Keep components like bearings in place.

Bushings

Provide low-friction surfaces for the moving parts.

Counterbalance Valves

Optional, used to prevent motor back-driving in some applications.

How Do Orbital Motors Work?

The mechanism of the orbital motor works primarily like this. The hydraulic fluid is pumped into the motor through the inlet port. The pressure difference between the chambers causes the inner rotor to rotate.

The rotation of the inner rotor is transferred to the drive shaft, which in turn produces the desired rotational motion and torque to perform work. Last, the hydraulic fluid exits through the outlet port, typically to be recirculated back into the hydraulic system.

Considerations When Buying Orbital Motors

When it comes to purchasing orbital motors, several factors should be taken into account to ensure you're making an informed decision. Here are some key considerations:

Technical Specifications

Displacement: Choose the right displacement size based on your application’s torque and speed requirements.

Maximum Operating Pressure: Make sure the motor can handle the hydraulic pressures it will be subjected to.

Rotational Speed: Ensure the motor meets the speed requirements for your application.

Quality and Certification

Certifications: Make sure the motor can handle the hydraulic pressures it will be subjected to.

Quality Inspection: If possible, inspect the motor or request test data to verify its performance and durability.

Material Quality: Opt for motors made from high-grade materials that offer durability and corrosion resistance.

Application Requirements

Compatibility: Ensure the motor is compatible with the existing hydraulic system, both in terms of size and hydraulic fluid compatibility.

Load Requirements: Understand the load the motor will be driving to select the right model.

Vendor Evaluation

Reputation: Research the vendor’s reputation for quality and customer service.

After-Sales Service: Ensure the vendor offers robust after-sales support, including warranties and maintenance services.

Lead Time: Evaluate the lead time for motor delivery, especially if it’s crucial for project timelines.

After-Sales Service

Technical Support: Availability of technical support post-purchase.

Parts Availability: Ensure that parts for the hydraulic cylinder are readily available.

Return Policy: Understand the return policy in case the product doesn’t meet your needs.

Orbital Motors Types By Design

Gerotor Motors

These motors use an inner and an outer rotor for the hydraulic fluid to act upon. The inner rotor has one less tooth than the outer rotor, creating an imbalance that leads to rotation.

Geroller Motors

Similar to Gerotor motors but use rollers instead of teeth to minimize friction and improve efficiency.

Disc Valve Motors

These motors use a disc valve to control the flow of hydraulic fluid, providing better performance under high-pressure conditions.

Orbital Motor Types By Speed and Torque

High-Speed, Low-Torque Motors

These are used in applications requiring high rotational speeds but relatively low torque.

Low-Speed, High-Torque Motors

Most orbital motors fall under this category, being particularly useful in applications that require high levels of torque at low speeds.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right component you want.

Mobile: +86-18006712375

Mail: eric@huanuohyd.com