Monoblock Valve Manufacturer

Monoblock Valve

A monoblock valve is a hydraulic control valve characterized by its one-piece construction, where all necessary components, including the spool, housing, and control elements, are combined into a single, self-contained unit. This design simplifies installation and maintenance while ensuring a high level of precision in fluid regulation. Monoblock valves find wide-ranging applications in industries such as agriculture, construction, and manufacturing, where precise control of hydraulic systems is essential for optimal performance.

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Monoblock Valves

Monoblock valves are indispensable components in hydraulic systems, known for their precision, efficiency, and space-saving design. Their one-piece construction and precise control make them essential in various industries, including agriculture, construction, and manufacturing. With advantages in installation, reliability, and maintenance, monoblock valves continue to play a vital role in optimizing hydraulic systems worldwide. If you have any specific questions or need further information, feel free to let me know!

Why Choose Monoblock Valves?

- Space Efficiency

- Simplified Installation

- Reduced Risk of Leakage

- Precision Control

- Versatility Across Industries

- Cost-Effectiveness

- Ease of Maintenance

- Customization Options

- Reliable Performance

- Proven Track Record

What Are Monoblock Valves Used For?

Monoblock Valves are integral components in hydraulic systems, providing precise control over fluid flow and pressure in a diverse range of applications across industries. Their versatility and reliability make them a critical asset in optimizing the performance of hydraulic machinery.

- Agricultural Machinery

- Construction Equipment

- Material Handling Machinery

- Manufacturing Processes

- Mining Equipment

- Forest Industry

- Marine & Offshore

- Material Processing Machinery

- Mobile Machinery

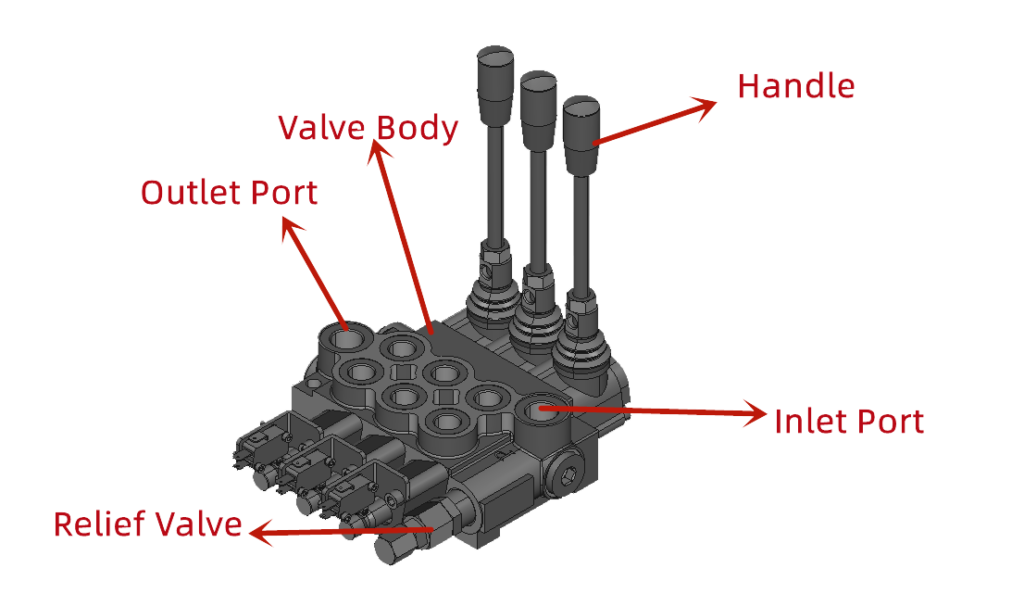

Monoblock Valves Parts

Understanding the parts of a hydraulic cylinder is essential for anyone involved in the purchasing, maintenance, or operation of hydraulic systems. Each component is engineered to perform a specific role, and the cylinder’s effectiveness relies on the quality and compatibility of its parts.

Valve Body

The housing, often referred to as the valve body, serves as the outer casing of the Monoblock Valve. It houses all the internal components and provides structural support.

Spool

The spool is a critical component that moves within the valve body to control the flow of hydraulic fluid. It has precise openings and grooves that determine the pathways for fluid to follow. The position of the spool dictates the flow direction and rate.

Actuator or Control Handle

The actuator, typically in the form of a lever or control handle, is the user interface for operating the Monoblock Valve. When the actuator is moved, it shifts the spool’s position, altering the fluid flow and pressure within the hydraulic system.

Pressure Relief Valve

Some Monoblock Valves may include a pressure relief valve as part of their design. This valve prevents excessive pressure buildup in the hydraulic system by diverting excess fluid back to the reservoir.

Check Valves

Check valves are often integrated into Monoblock Valves to allow one-way flow of hydraulic fluid. They ensure that fluid can flow in one direction while preventing backflow in the opposite direction.

Control Mechanism

Monoblock Valves may have various control mechanisms, such as detents or spring-centered positions. These mechanisms provide tactile feedback and help the user maintain control over the valve’s position.

How Does Monoblock Valve Work?

How exactly does a monoblock valve work? This guide breaks down the operational principles behind this essential device.

- Spools and Passageways: Inside the valve, there are one or more spools. A spool is a cylindrical piece that can move within the valve body. It contains channels, or passageways, that connect the various ports.

- Positioning of the Spool: The position of the spool determines the flow path of the hydraulic fluid. In a monoblock valve, the spool can be moved manually (by a lever or knob) or through some kind of actuator (like a solenoid) depending on the specific design.

- Neutral Position: In the neutral position, the spool is centered, which means it’s blocking all flow paths. This prevents any fluid from moving, maintaining a static condition.

- Directional Control: When the spool is moved from its neutral position, it opens specific passageways. This allows hydraulic fluid to flow from the inlet to the selected outlet port(s), enabling the hydraulic actuator (like a cylinder or motor) to move.

Overall, a monoblock valve is a fundamental component in hydraulic systems, allowing for the precise control of fluid flow and pressure, which is crucial for the operation of various machinery and equipment.

Considerations When Buying Monoblock Valves

When buying monoblock valves for your business, it's important to consider several factors to ensure you select the right valves that meet your specific requirements. Here are some key considerations:

Valve Type and Functionality: Determine the type of monoblock valve you need (e.g., directional control valve, flow control valve, pressure relief valve) based on the requirements of your hydraulic system.

Flow Rate and Pressure Rating: Ensure the valve’s flow rate and pressure ratings are compatible with your hydraulic system’s specifications. Choosing a valve with the correct capacity is crucial for optimal performance.

Number of Spools: The diameter of the rod impacts the cylinder’s overall strength and speed.

Functionality and Control: Consider whether you need manual, mechanical, or solenoid-operated valves. This choice depends on the level of automation and control precision required for your application.

Compatibility with Hydraulic Fluid: Ensure the valve is compatible with the type of hydraulic fluid you’re using. Some valves are designed for specific fluids, and using the wrong one can lead to operational issues.

Size and Mounting Options: Consider the physical dimensions of the valve and whether it will fit within your system’s layout. Additionally, choose the appropriate mounting option (e.g., panel mount, subplate mount) for your application.

Certifications and Standards: Check if the valves comply with industry standards and certifications. This ensures that the valves meet quality and safety requirements.

Environmental Conditions: If your hydraulic system operates in harsh environments (e.g., high temperatures, corrosive atmospheres), choose valves with appropriate coatings or materials for enhanced durability.

Reliability and Durability: Look for valves from reputable manufacturers known for producing high-quality, durable components. Reliability is crucial to minimize downtime and maintenance costs.

Price and Budget: Consider your budget constraints. While it’s important to find cost-effective options, prioritize quality and compatibility over purely seeking the lowest price.

After-Sales Support and Warranty: Choose a supplier that offers good after-sales support and provides warranties for their products. This can be crucial in case of any issues or defects.

Supplier Reputation and Experience: Select a reliable supplier with a good reputation in the industry. Established suppliers often have a track record of providing quality products and services.

By carefully considering these factors, you can make an informed decision when purchasing monoblock valves for your hydraulic systems. This ensures that the valves you choose are well-suited to your specific needs and will contribute to the efficient operation of your machinery.

Monoblock Valves Types By Control Mechanism

Manual Control Valves

These valves are operated manually, typically using levers or knobs. They are often used in applications where operators need direct control.

Solenoid-Operated Valves

These valves are actuated by an electric solenoid, allowing for remote or automated control.

Pneumatic Control Valves

These valves are actuated by a pneumatic system, allowing for remote or automated control.

Pilot-Operated Valves

These valves use the pressure from a pilot line to control the position of the main spool. They are often used in high-pressure applications.

Monoblock Valves Types By Structure

Monoblock Valves

A monoblock valve, also known as a monoblock directional control valve, is a type of hydraulic valve used in hydraulic systems to control the flow and direction of hydraulic fluid. It is called “monoblock” because it is constructed from a single block of material, typically cast iron or steel. This design provides durability, compactness, and resistance to high-pressure environments. The key features of a monoblock valve include:

Sectional Valves

A sectional valve, also known as a sectional control valve, is a type of hydraulic valve used in complex hydraulic systems to control the flow of hydraulic fluid. Unlike monoblock valves, sectional valves are modular in design, consisting of individual sections that can be assembled together to create a customized valve configuration.

Frequently Asked Questions

We have compiled the most frequently asked questions about our monoblock valves here for your convenience, but please feel free to contact us if you have any additional questions.

What Is a Monoblock Valve?

A monoblock valve, also known as a monoblock directional control valve, is a type of hydraulic valve used to control the flow and direction of hydraulic fluid in a hydraulic system. It is called “monoblock” because it is constructed from a single block of material.

Where can I purchase monoblock valves?

Monoblock valves can be purchased from hydraulic equipment suppliers, distributors, and manufacturers. They are also available through online marketplaces and specialized hydraulic component retailers. Remember to consult with a qualified hydraulic systems professional or supplier for specific advice and recommendations regarding the selection, installation, and maintenance of monoblock valves for your application.

What Are The Main Components of A Monoblock Valve?

The main components of a monoblock valve include the valve body (constructed from a single block of material), one or more spools (which control the flow of hydraulic fluid), ports for hydraulic connections, and control mechanisms (such as levers or knobs).

How Do You Maintain and Troubleshoot A Monoblock Valve?

Regular maintenance includes checking for leaks, ensuring proper operation of control mechanisms, and inspecting spools for wear. Troubleshooting may involve identifying and fixing issues with leaks, poor valve response, or other operational problems.

What Is The Turnaround Time On My Order?

It takes us around 7 to 10 business days to produce the standard monoblock valves and 10 to 15 business days for customized valves. On the other note, the transit time will take 7 to 10 business days if by express. Reach us online for your custom and bulk orders so we can explain the actual turnaround time based on the specific details of your order.

What Is Your MOQ For The Order?

For as low as one unit of monoblock valve, you can secure your order and we can manufacture and deliver it to you according to your requirements.

Can I Get a Sample Before Place The Batch Order?

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-3 days, depends on the specifications you need.

Request a sample now!

What Is Your Warranty For Your monoblock valves?

Quality is our culture. All of our hydraulic components are provided with a 1-year warranty.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right component you want.

Mobile: +86-18006712375

Mail: eric@huanuohyd.com