Proportional Load Sensing Valve Manufacturer

Proportional Load Sensing Valve

HNDRS09

HNTRM10/15/20/25

HNDLPF12

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Proportional Load Sensing Valve

A Proportional Load Sensing Valve is a sophisticated hydraulic valve that adjusts fluid flow in proportion to the load. It ensures that the hydraulic system operates at peak efficiency by maintaining optimal pressure for each specific task.

This article discusses popular topics on proportional load sensing valves, including their applications, mechanisms, buying considerations, as well as the components/parts of valves. With this knowledge, you’ll be better equipped to make informed decisions, whether you’re selecting a new valve, performing maintenance, or troubleshooting issues.

Advantages of Proportional Load Sensing Valve

Dynamic Adaptation

These valves automatically adjust fluid flow and pressure according to the system's real-time needs, reducing energy wastage.

Tailored Solutions

Many manufacturers offer customization to meet specific operational requirements, providing an even greater level of optimization.

Precision Control

The ability to adjust fluid flow and pressure in real-time allows for more accurate and efficient operation of hydraulic machinery.

Broad Applications

Suitable for a wide range of hydraulic systems, from industrial machinery to mobile equipment.

Wide Range Applications

Can be used in various industrial settings, from manufacturing and construction to utilities and logistics.

Easy Integration

Designed to be compatible with existing hydraulic setups, making it easier to retrofit or upgrade your systems.

High-Quality Construction

Often made with industrial-grade materials and to stringent quality standards, ensuring long-term reliability.

Cost Savings

Lower energy consumption translates into substantial long-term cost savings.

Safety Features

Advanced models come with built-in safety protocols, such as emergency stop functions and overload protection.

What Are Proportional Load Sensing Valves Used For?

Proportional Load Sensing Valves are a cornerstone in modern hydraulic systems, offering a level of control and efficiency unparalleled by traditional valves. Given their versatile nature, they find applications across a wide range of industries and machiner

Below a selection of applications and examples of radio control solutions which can be seen by clicking on the respective category.

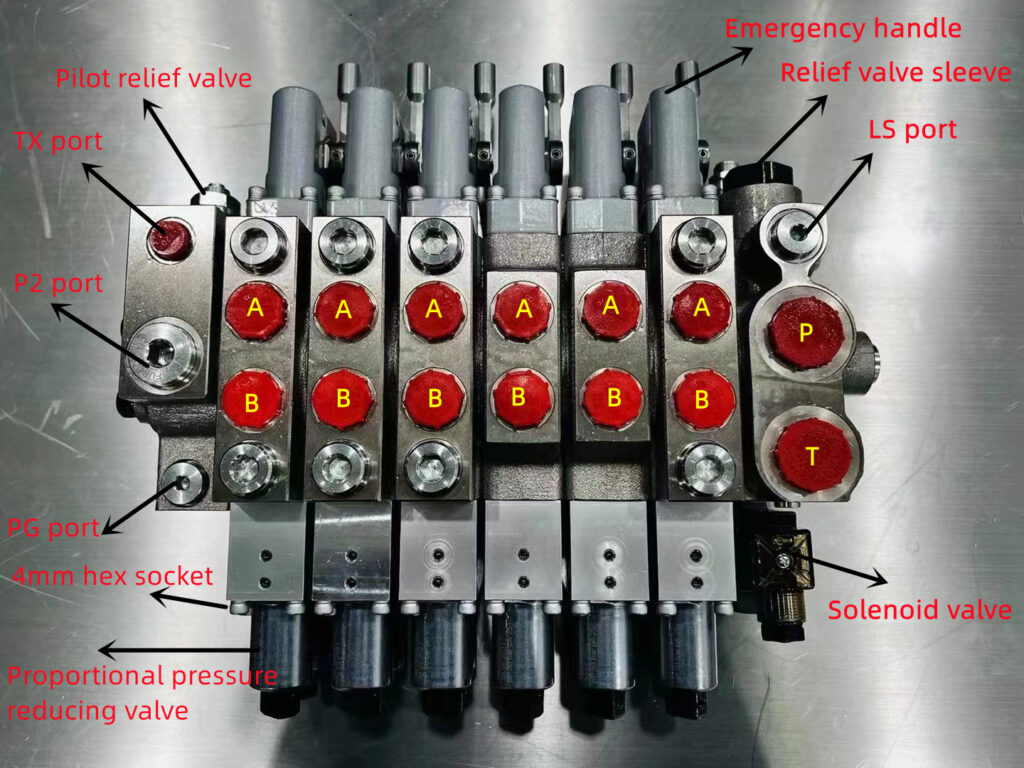

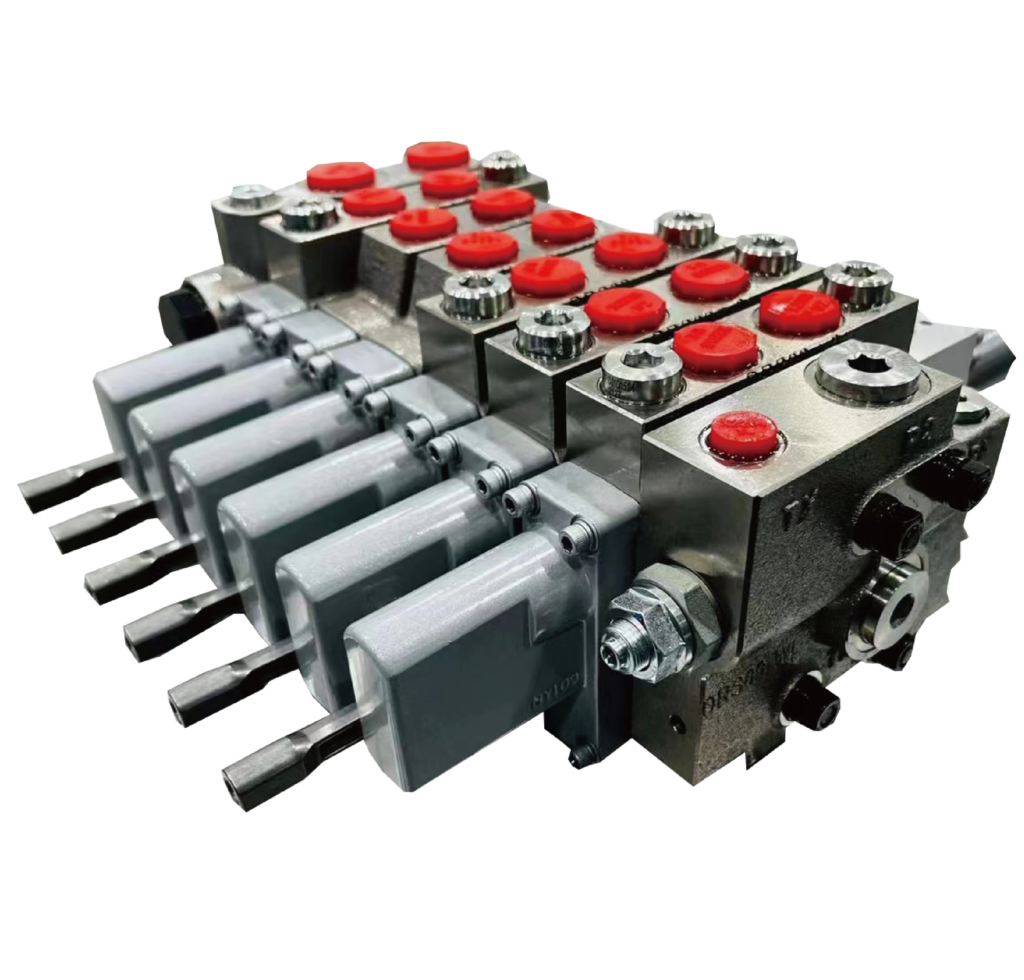

Proportional Load Sensing Valve Parts

Understanding the components that make up a Proportional Load Sensing Valve can help you appreciate its functionality and make informed decisions when purchasing or maintaining one. Given your focus on quality and technical details, a deep dive into the anatomy of this valve can provide crucial insights. Here’s a breakdown of the key components:

Valve Body

The main structure that holds all other components, usually made from industrial-grade metals for durability.

Proportional Pressure Reducing Valve

They are designed to offer precise control over pressure levels by adjusting them in real-time, based on electric signals.

Relief Valve and LS Valve

Adjust the pressure.

Manual Lever

Some models also include a manual control option as a backup.

Solenoid Actuator

An electromechanical component that moves the spool in response to electrical signals.

Spool

The cylindrical component that moves within the valve body to regulate fluid flow.

How Does Proportional Load Sensing Valve Work?

Here’s a deep dive into how a Proportional Load Sensing Valve operates:

At its core, a Proportional Load Sensing Valve adjusts the flow and pressure of hydraulic fluid in proportion to the load or demand of the hydraulic system. It does this by dynamically sensing the load conditions and adjusting the valve’s internal components accordingly.

Considerations When Buying Proportional Load Sensing Valves

Purchasing a Proportional Load Sensing Valve is a significant investment that can substantially impact the efficiency and performance of your hydraulic systems. Given the technical complexity of these valves, making an informed decision is crucial. This guide aims to outline the key considerations you should take into account, particularly for discerning customers like Jeff Jarvis, who focus on quality, efficiency, and a strong return on investment.

#1 Understand Your Application Needs

Operating Pressure and Flow : Know the maximum and minimum pressure and flow rates that your system operates at.

Load Variability: Consider how often and how dramatically the loads in your system change, as this will impact the type of valve you need.

#2 Compatibility and Integration

System Compatibility: Ensure the valve you choose can be integrated into your existing hydraulic system without requiring extensive modifications.

Electrical Requirements: Check if the electrical specifications of the valve match your system’s capabilities. interference.

#3 Material and Construction Quality

Material Durability: Opt for valves made from high-quality, corrosion-resistant materials.

Industry Certifications: Look for valves that meet or exceed industry standards and certifications to ensure quality and safety.

#4 Sensing and Control Capabilities

Sensors: Make sure the valve has reliable pressure and flow sensors for accurate operation.

Control Options: Depending on your needs, you may want a valve that can be manually overridden or one that can be integrated into automated systems.

#5 Vendor Reputation and Reliability

Vendor Reviews: Research the vendor’s reputation in the market, looking at both customer reviews and expert opinions.

Warranty and Support: A strong warranty and robust customer support are indicators of a reliable vendor.

#6 Technical Support and Training

Installation Guidance: Check if the vendor offers installation support or guidelines.

Training: Find out if training is provided for operators to understand the valve’s functionalities.

#7 Maintenance and Longevity

Maintenance Requirements: Understand the level of maintenance the valve will require and whether you have the resources to manage it.

Availability of Spare Parts: Ensure that replacement parts are readily available to minimize downtime.

#8 Budget and Cost Effectiveness

Initial Investment: Calculate the upfront costs, including the valve, installation, and any system modifications.

Long-Term Costs: Factor in maintenance, energy savings, and the valve’s lifespan to understand its long-term cost-effectiveness.

ROI: Consider how the valve will improve system efficiency and how quickly you can expect a return on your investment.

#9 Additional Features

Safety Measures: Look for additional safety features like emergency stops or overload protection.

Customization: Some vendors offer customization options to better suit your specific needs.

Proportional Load Sensing Valve Types By Schematic

Valve Spool Schematic

There are totally 3 different types spool in our valve. They are respectively O type, Y type and YJ type.

What is the main difference between them? Here is a deep dive into how to choose it:

When you have counterbalance valve or hydraulic lock in your cylinder, either type will work for you. But if you do not have this valve, O type is the best choice for you.

Proportional Load Sensing Valve Types By Structure

Open Center

Open Center is usually applied to the fixed displacement pump system.

Closed Center

Closed Center could be applied to the dual power hydraulic system composed of load sensing pump and fixed displacement pump, or can also be used in load sensing pump system individually.

Proportional Load Sensing Valve Types By Max Flow Rate

HNDLPF12

Loading..........

The Data is Not Available

HNDRS09

Loading..........

The Data is Not Available

Customer Application

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right component you want.

Mobile: +86-18006712375

Mail: eric@huanuohyd.com