Latest News

The latest and greatest project news

What Is The Role of Proportional Load Sensing Valves in Explosive Trucks: A Comprehensive Guide?

The world of explosive handling is fraught with risks at every turn. Ever wondered how explosive trucks manage to transport volatile materials without compromising safety and efficiency? One critical component you might not have considered is the proportional load sensing valve. These valves are the unsung heroes ensuring that explosive trucks operate under the safest and most efficient conditions.

So, what exactly is the role of a proportional load sensing valve in these specialized vehicles? They are the unsung heroes in this context. Simply put, they are essential for maintaining the safety and operational efficiency of the hydraulic systems within the truck.

Let’s delve deeper to understand why proportional load sensing valves are indispensable in this industry.

Table of Contents

What Are Proportional Load Sensing Valves?

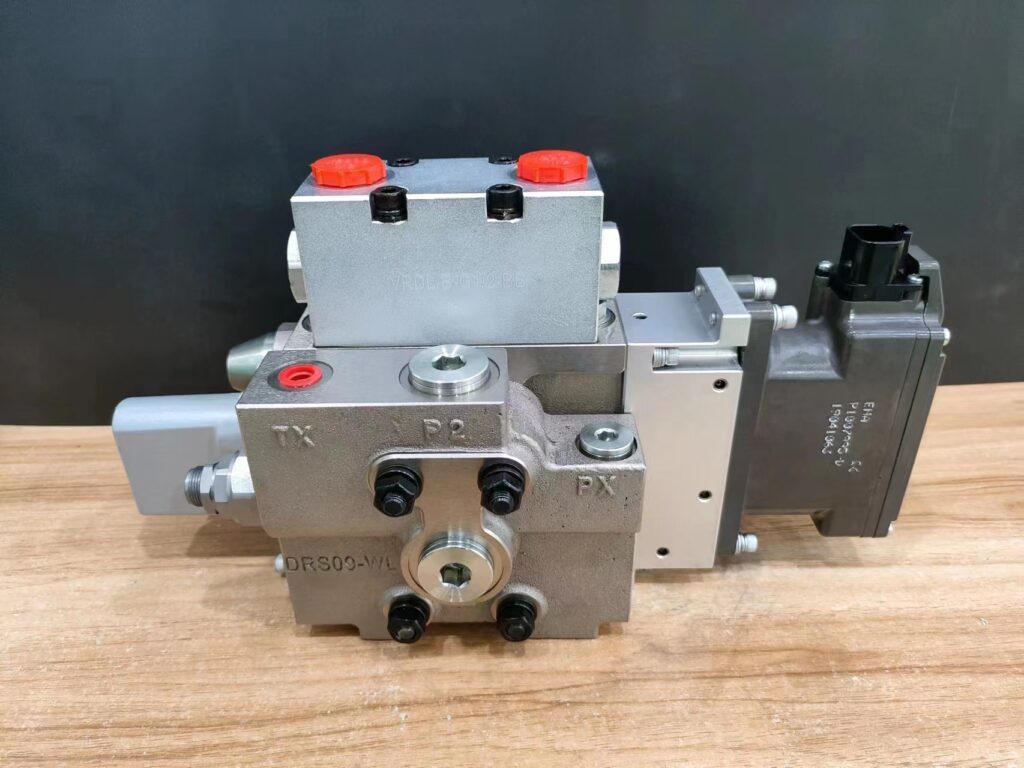

In essence, a proportional load sensing valve is a high-precision hydraulic valve that dynamically adjusts fluid flow and pressure to meet the actual needs of the system. When it comes to explosive trucks, these valves add an extra layer of safety and efficiency, making them invaluable components.

How Do Proportional Load Sensing Valves Function?

A proportional load sensing valve adjusts the fluid flow and pressure within the hydraulic system based on the actual system requirements. Unlike conventional valves that offer a static, fixed setting, these valves dynamically adapt in real-time, providing precise control over hydraulic functions.

Why Are They Essential in Explosive Trucks?

Explosive trucks transport highly volatile materials; hence, even a slight imbalance in hydraulic flow or pressure can lead to disastrous consequences. Proportional load sensing valves act as guardians that maintain a delicate balance in the hydraulic systems, keeping the risk of accidental explosions at bay.

What Makes Them Ideal for Explosive Trucks?

Safety: The foremost concern in explosive trucks is ensuring safety during transport. Any hydraulic system failure could lead to disastrous consequences, including potential explosions. Proportional load sensing valves offer an extra layer of safety by ensuring that hydraulic systems work within optimal parameters.

Efficiency: A secondary yet important factor is operational efficiency. By automatically adjusting the hydraulic fluid flow to meet actual needs, these valves reduce energy consumption and result in long-term cost savings.

How Do They Improve Safety in Explosive Trucks?

Safety is paramount when it comes to the transportation of explosive materials. A key player in ensuring this safety within the hydraulic systems of explosive trucks is the proportional load sensing valve. But how exactly do these valves improve safety? Let’s break it down.

Real-time Adjustments for Precise Control

One of the main features of a proportional load sensing valve is its ability to make real-time adjustments to the hydraulic fluid flow and pressure. Unlike traditional valves that have fixed settings, these valves adapt dynamically. This adaptability allows for much finer control over the hydraulic functions of the truck, reducing the chance of sudden, uncontrolled movements that could be hazardous, especially when transporting volatile materials.

System Monitoring and Feedback Loop

These valves come equipped with sensors that continuously monitor various system parameters such as pressure and flow rates. If any irregularities are detected, the valve can immediately adjust to bring the system back to its optimal operational state. This feedback loop is crucial for preventing potential accidents due to hydraulic system failures or malfunctions.

Energy Efficiency Reducing Heat and Wear

Hydraulic systems can generate a lot of heat, and excessive heat can be a safety concern, especially in explosive trucks. Proportional load sensing valves improve energy efficiency by only delivering the amount of fluid required for each specific operation, thereby reducing the heat generated within the hydraulic system. Less heat means less wear and tear on the components, and more importantly, a lower risk of heat-induced malfunctions or failures that could compromise safety.

Reduced Risk of Hydraulic Shock

Hydraulic shock, also known as “water hammer,” can occur when fluid in a hydraulic system suddenly changes direction or speed. This can place significant stress on the system and may result in failures that have serious safety implications. Proportional load sensing valves mitigate this risk by providing smoother, more controlled fluid transitions, making hydraulic shocks less likely to occur.

Conclusion

The importance of proportional load sensing valves in explosive trucks cannot be emphasized enough. These valves are not just components but critical safety tools that protect both life and property. If you haven’t yet integrated them into your explosive trucks, now is the time to act.

So there you have it, a comprehensive guide on why proportional load sensing valves are crucial in the realm of explosive trucks. Safety should always be your priority, and these valves are the means to ensure it.

That’s the long and short of it. Safety first, always.

Recent Posts

Share This Story, Choose Your Platform.

Leave A Comment

Your email address will not be published. Required fields are marked *